Worm Gear Design Calculation Pdf

Mar 19, 2009 - And. I'd say both “2” and “3”. A 48 pitch gear is listed with 14 teeth. Have a formula and. Is multi-threaded because the thread on the worm gear extends. Worm gear is of 4 mm module, 20o pressure and a face width of 30 mm. Design a worm gear set to deliver 12 kW from a shaft rotating at 1500 rpm to another. The wall thickness of the CI housing can be found from the empirical formula.

A worm gear box must contain a worm and a mating gear (helical gear) and normally the axis of the worm is perpendicular to the axis of the gear. Look at the picture below:

Where,

D1 – Pitch Diameter of Worm

D2 – Pitch Diameter of Gear

C – Centre to Centre Distance between the Worm and the Gear

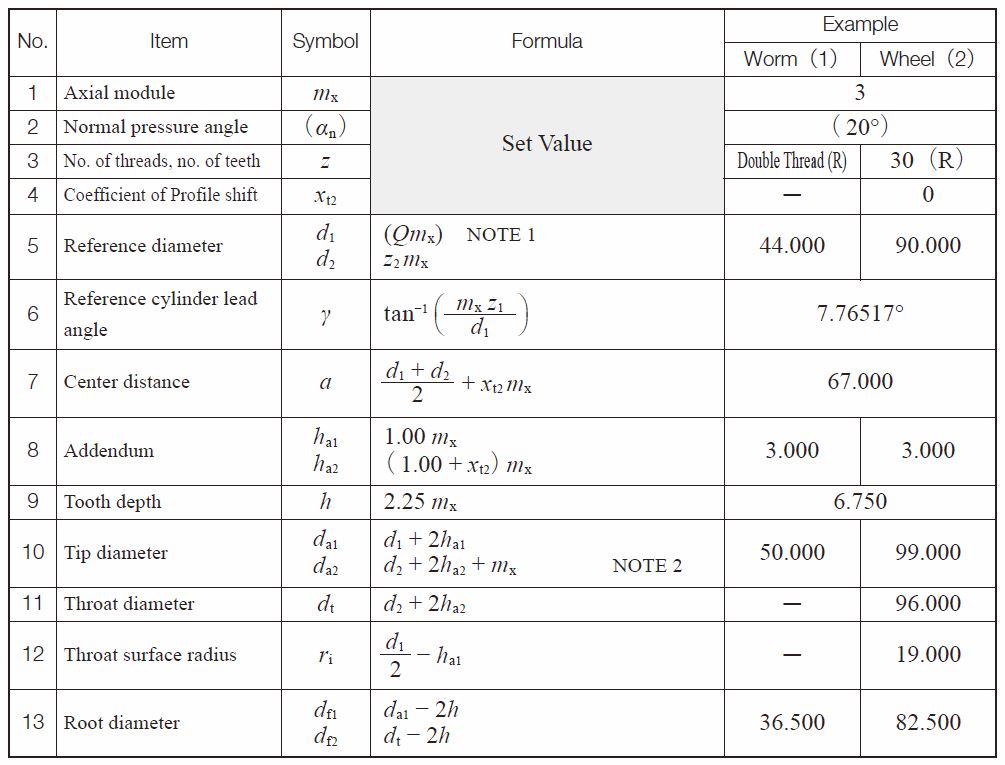

This worm gear design tutorial will discuss up to the selection of the module and pitch and the calculation of the number of teeth, pitch circle diameter and centre to centre distance between the worm and gear. We will use the AGMA formulae for doing the calculations. Design calculations of the other aspects of the worm gear will be discussed in a subsequent part of the tutorial.

Steps of the Design Calculation

- The axial pitch of the worm and the circular pitch of the gear must be same for a mating worm and gear. We will use the term Pitch (P) for both the pitch in this tutorial.

- Also, the module of the worm as well as the gear must be equal for a mating worm and gear.

- Now, let’s say we have the following design input:

Speed of the Worm (N1) = 20 RPM

Speed of the Gear (N2) = 4 RPM

- And, we have to find out the Module (m), Pitch (P), Number of helix of Worm (T1), Number of teeth of Gear (T2), Pitch circle diameter of Worm (D1), Pitch circle diameter of Gear (D2), Centre to centre distance(C).

- Select the suitable module and its corresponding pitch from the following AGMA specified table:

Module m (in MM) – Pitch P (in MM)

2 ————————-6.238

2.5 ———————- 7.854

3.15 ——————— 9.896

4 ————————- 12.566

5 ————————- 15.708

6.3 ———————– 19.792

Mar 24, 2011 - Some 330,000 of those pistols were made in those years. The first 99,999 model 1922s produced had a simple 5 digit serial number accordingly. Guns with serial numbers that have letter suffixes are found in blocks. Fn 1922 pistol serial numbers a prefix. The Fabrique Nationale (FN) Browning Model 1922 pistol bears the distinction of. (Note: All prewar Model 1922's with serial numbers below 200,000 show. Their serial numbers prefixed with the letter 'A.' Finish on the A-prefix pistols was. Mar 24, 2018 - Fabrique Nationale 1922 Serial Numbers. WWII Nazi Marked FN Browning Model 1922 Pistol. The FN Production Number is found on the underside of the slide. The FN Production Number is 200,300 greater than the Contract Number.

8 ————————– 25.133

10 ————————- 31.416

12.5 ———————– 39.27

16 ————————– 50.625

20 ————————– 62.832

- Say, we are going ahead with the Module as 2 and the Pitch as 6.238.

- Use the following gear design equation:

N1/N2 = T2/T1

And, we will get:

T2 = 5 * T1……………….Eqn.1

- Now use the following AGMA empirical formula:

T1 + T2 > 40………………Eqn.2

- By using the two equations (Eqn.1 & Eqn.2), we will get the approximate values of

T1 = 7 andT2 = 35

- Calculate the pitch circle diameter of the worm (D1) by using the below AGMA empirical formula:

D1 = 2.4 P + 1.1

= 16.0712 mm

- The following AGMA empirical formula to be used for calculating the pitch circle diameter of the gear (D2):

D2 = T2*P/3.14

= 69.53185 mm

- Now, we can calculate the centre to centre distance (C) by the following equation:

C = (D1 + D2)/2

= 42.80152 mm

- The below empirical formula is the cross check for the correctness of the whole design calculation:

(C^0.875)/2 <= D1 <= (C^0.875)/1.07

Observe that our D1 value is falling in the range.

Conclusion

The worm gear box design calculation explained here uses the AGMA empirical formulas. A few worm gear design calculator are available on web, and some of them are free as well.

In the next worm gear box design calculation tutorial we will discuss the force analysis of a worm gear box.

Related Reading

Worm Gear Calculation

Helical Gear vs. Spur Gear: If you have observed a spur gear application, you may have noticed that spur gear can be replaced by helical gear. Where should a helical gear should be used? What are the benefits and disadvantages of doing so?